Waterproofing of terraces with bituminous membranes

RELATED MATERIALS

ISOGUM P Plastomeric bituminous membrane (APP) reinforced with polyester cloth of 180 g/m

ISODIEN 4 PF ALU Elastomeric bituminous membrane covered with aluminium sheet

DUROCRET Polymer-modified cement mortar

RAPICRET Fast-setting patching mortar

ADIPLAST Polymer latex for multiple improvements of mortars

ISOPAST Bituminous emulsion

ISOLAC-BT Bituminous varnish

ISOMAC Bituminous mastic

ISOFLEX Elastomeric waterproofing membrane

ISOFLEX-T25 Elastomeric waterproofing membrane

I. NATURE OF THE PROBLEM – REQUIREMENTS

Waterproofing for terraces must be absolutely watertight, reliable, resistant to adverse weather conditions and long lasting.

Also it must display elasticity and efficient bonding to the substrate.

II. SOLUTION

Waterproofing with ISOGUM, plastomeric bituminous membranes, meets the above requirements. ISOGUM is made from a specially formatted mixture of bitumen and polymers from Atactic Polypropylene (A.P.P.), reinforced with polyester fabric. It provides an effective, affordable and easily-applied solution for waterproofing terraces, since it can be stuck down by heating with a blow-torch, without the need of hot oxidised bitumen (bituminous adhesive).

It is suitable for waterproofing terraces at the time of their construction or later.

Where waterproofing is the final surface layer, it is recommended that action is taken for its protection from UV radiation and thus prolongation of the membranes life. This can be done by using bituminous membranes with a covering of mineral chippings (either white or grey) or by the subsequent covering of the waterproofing with an other layer, such as paving slabs or 2-3 cm graded gravel layer, 6-8 cm thick. In the latter case, it is recommended that geotextile is put between the waterproofing and gravel, to protect the waterproofing from “injuring”.

III. APPLICATION

Substrate preparation

The substrate should be thoroughly cleaned from any loose particles, grease, dust etc.

Any necessary repairs or alterations to the gradient should be carried out using a strong cement mortar (cement:sand = 1:2 to 1:3), reinforced by the addition of ADIPLAST polymer latex. It is recommended that bonding of the cement mortar to the substrate is reinforced by applying a bonding layer to which ADIPLAST is also added (cement : sand : ADIPLAST : water = 1 : 1 : 0,5 : 0,5 by volume parts).

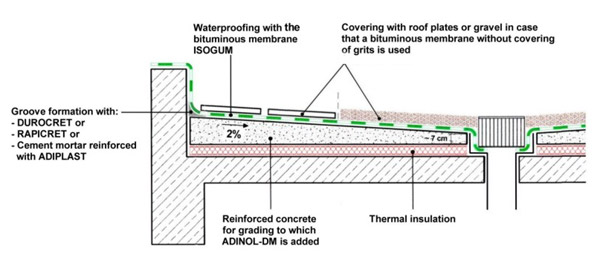

Where the terrace intersects the vertical structures a groove must be formed using DUROCRET polymer modified cement mortar or a cement mortar reinforced with ADIPLAST polymer latex. When fast work is required, RAPICRET fast-setting cement mortar can be used instead.

Consumption of DUROCRET: 1,9-2,7 kg/m groove’s length.

This prevents the bituminous membranes from being folded at a right angle, which could result in cracking.The terrace, which should be dry, is primed with a suitable bitumen primer, such as ISOPAST bitumen emulsion diluted with water or ISOLAC bitumen varnish.

ISOPAST consumption: approx. 0,3 kg/m2.

ISOLAC consumption: approx. 0,3 kg/m2.

ISOGUM application

The bituminous membranes are heated with a blowtorch and stuck to the surface, starting from the lower points, so that there will be no joints against the water flow. The film covering the inner side of the membrane melts on contact with the flame and facilitates the bonding of the bituminous membranes to the surface. Adjacent membrane felts should overlap each other at a width of approx. 10 cm.

Once the bituminous membranes have been laid, the joints are especially treated with a blowtorch and sealed by being pressed with an iron roll, in order to ensure good bonding. Where bituminous membranes with chips is used, the bonding process in the overlapped areas involves a significant loss of chips. To ensure that the coverings’ protection against UV radiation is adequate, a coating with ISOFLEX is recommended along the entire length of the joints.

The waterproofing is extended about 50 cm up to the sides of vertical surfaces (parapets, stairs, termination etc.), in order to form a watertight basin.

It is recommended that the edges of the bituminous membranes are fixed to the vertical surfaces with aluminium strips, 2 mm thick and 3 cm wide. Galvanised nails and washers are used to fasten them.

The space between the strip and the vertical surface should be sealed with special bituminous mastic ISOMAC. Wherever there is an interruption to the waterproofing (pipes, rain pipes, metal bases etc.), this should be similarly sealed with the same mastic.